Demolishing a wind turbine is not a small feat. With structures soaring as high as skyscrapers and blades spanning the width of a jumbo jet’s wings, the demolition process must account for the enormous “heights and scale in wind turbine demolition.” This article will delve into the specialized approaches and safety protocols necessary to take down these giants in the renewable energy world.

Key Takeaways

- Demolishing wind turbines is highly complex, involving the disassembly of large blades, towers, and foundations while ensuring worker safety at extreme heights and managing logistics in often remote locations.

- Wind turbine demolition requires meticulous planning, including comprehensive risk assessments, technical dismantling procedures, and provision of emergency response capabilities due to the intricate designs and mechanical systems of turbines.

- The safety and environmental considerations of wind turbine demolition are paramount, guided by a multitude of regulations and standards, and necessitate measures such as recycling and site restoration along with scaling safety practices for future technological advances.

Understanding the Challenges of Wind Turbine Demolition

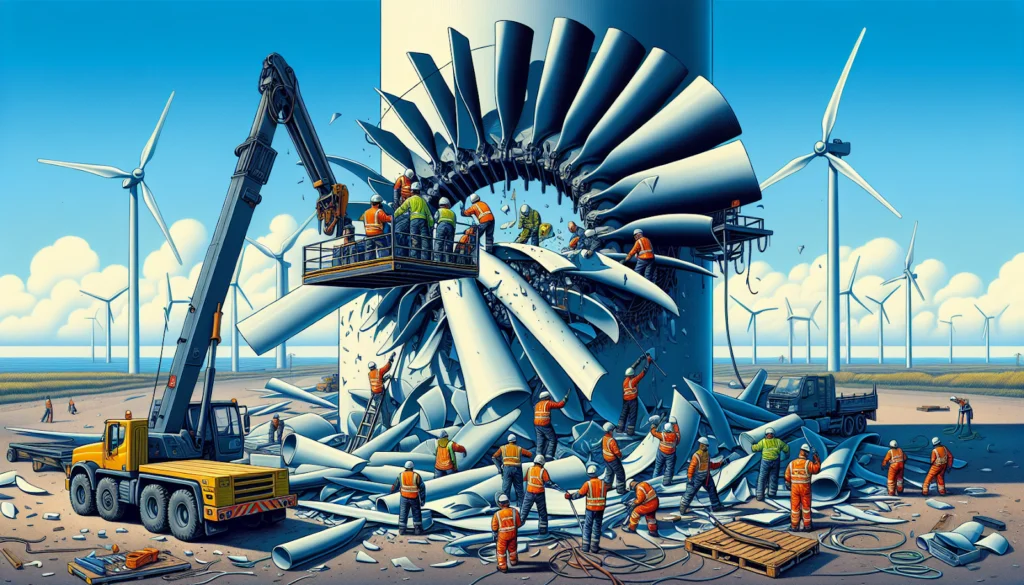

Demolishing wind turbines is a complex task. These structures, reaching the heights of skyscrapers and stretching across vast landscapes, pose unique challenges that demand innovative solutions. The sheer size of these turbines, particularly the large rotor diameters, significantly increases demolition complexity. Picture trying to carefully disassemble the wings of a jumbo jet, but at dizzying heights and often in remote locations. This necessitates specialized equipment and transportation methods to handle oversized components. Some of the key challenges in demolishing wind turbines include:

- Handling the large rotor blades

- Disassembling the tower structure

- Removing the foundation

- Ensuring worker safety at extreme heights

- Managing logistics in remote locations

Addressing these challenges requires careful planning and coordination to ensure a safe and efficient demolition process.

The Scale of Modern Wind Farms

The dramatic growth in the scale of modern wind farms reflects the rising significance of wind energy in our global energy mix. As wind energy projects increase in size, this larger scale directly influences demolition costs and adds complexity to the decommissioning process. Demolition involves more than just dismantling the turbines. Managing the substantial volume of materials that must be dismantled and transported requires careful planning and strategy.

The logistics are complex, involving not just the turbines themselves but all the associated infrastructure that supports them, as studied by the National Renewable Energy Laboratory.

High-Stakes Heights

Demolishing wind turbines, including offshore wind turbines, becomes even more complex due to their towering height. Picture a structure taller than the Statue of Liberty, with blades that can exceed 50 meters in length. The scale of these structures necessitates specialized dismantling equipment and a team of expert workers to manage the high-stakes demolition process.

Due to the considerable height and confined spaces involved, high-angle rescue techniques are vital for effectively conducting human injury rescues within wind turbines. Imagine trying to evacuate an injured worker from the top of a skyscraper—but in a location that’s often remote and windy.

Complexity in Construction and Demolition Operations

Wind turbines, specifically horizontal axis wind turbines, are not merely tall towers with spinning blades; they house complex mechanical systems involving significant amounts of diverse materials, all working together to harness wind power. These materials are carefully chosen and assembled by wind turbine manufacturers and include:

- Metal

- Concrete

- Fiberglass blades

- Copper

This complicates demolition and recycling efforts. Furthermore, demolition operations face the risk of fire due to mechanical friction and electrical short circuits in the turbines, enhanced by the presence of hydraulic fluid and other flammable substances.

Picture removing a fireplace from a house; only the fireplace is several stories high and packed with potentially flammable materials.

Tackling the Technicalities: Wind Turbine Deconstruction Steps

The actual steps involved in wind turbine demolition go beyond merely “tearing things down”; a detailed technical process needs to be followed, from site hazard identification to emergency response capability. The complexity of wind turbine design, from unguarded moving parts to electrical components, necessitates a detailed hazard evaluation to ensure worker safety.

It’s like dismantling a car, but each component is much larger, and the stakes are a lot higher.

Site Hazard Identification

Identifying potential hazards through a comprehensive risk assessment is a prerequisite before any demolition can commence. This includes falls, electrical issues, and machinery operations. Site-specific planning must also anticipate a variety of other hazards, from stakeholder coordination and site topography to utility locations and environmental factors. To ensure a safe and efficient process, it is crucial to identify additional considerations that may arise during the project.

It’s not just about identifying what could go wrong during the demolition process, but also what the potential impacts could be on the surrounding area and community.

Dismantling the Turbine Blades

The challenges amplify when it’s time to dismantle the turbine blades. These blades are designed to withstand hurricane-force winds and are not easily crushed, creating difficulties in their disposal. The blades are cut into smaller sections using diamond-encrusted industrial saws and then transported for disposal.

The sheer size of the blades, often as long as a Boeing 747 wing, requires special handling and poses significant logistical challenges.

Emergency Response Capability

In wind turbine demolition, having an emergency response capability is a vital aspect. Given the remote locations and high stakes involved, clear evacuation plans, dedicated emergency response teams, and coordination with local emergency medical services are critical.

In addition to this, real-time monitoring systems during demolition can enhance worker safety by offering immediate information on the structural integrity and ensuring a safer work environment.

Safety First: Adhering to Regulations and Standards

In wind turbine demolition, safety takes precedence. This is governed by specific standards and regulations to ensure the safety of operations. The ANSI/ASSP A10.21 standard was created to address the unique construction and demolition challenges of wind turbines, prompting enhanced safety protocols.

Establishing Minimum Safety Requirements

In wind turbine demolition, the critical step is to establish minimum safety requirements. This includes:

- Developing an energization plan to protect workers from electrocution risks

- Conducting regular audits and investigations to identify hazards and update safety procedures

- Providing workers with adequate personal protective equipment

- Training workers on the proper use of personal protective equipment

This critical step helps protect them from a variety of hazards during the demolition process.

Developing a Comprehensive Safety and Health Plan

To ensure worker safety, it’s necessary to develop a comprehensive safety and health plan. The plan must establish clear communication protocols and emergency communication systems to prevent accidents, simplify coordination, and ensure swift alerting and response in emergencies.

Regular safety meetings must be conducted to review and update safety procedures in accordance with any new safety concerns or regulatory updates that emerge.

Ensuring Adequate Training and Equipment

It is crucial to ensure workers have adequate training and equipment in wind turbine demolition. Workers need specialized training to operate new safety equipment, such as enhanced personal protective equipment (PPE) and automated machinery.

The use of modern technology, like real-time monitoring systems and virtual reality (VR) for training and simulation, can significantly enhance safety outcomes.

Environmental Considerations in Wind Turbine Demolition

Wind turbine demolition also brings significant environmental considerations, in addition to the technical and safety aspects. From recycling and reusing materials to mitigating environmental impact and identifying additional concerns, it’s vital to consider the potential ecological effects of demolition activities.

For instance, environmental protection measures such as dust suppression systems are essential to controlling airborne particulates during demolition.

Recycling and Reusing Materials

To reduce the environmental impact and manage waste during wind turbine demolitions, industrial-scale recycling of turbine blades and other components is vital. Recycling turbine blades made of composite materials like fiberglass involves innovative solutions, such as pyrolysis to break down organic components and repurposing the blades into construction materials. This not only aids in recycling but also contributes to a circular economy.

Mitigating Environmental Impact

Mitigating environmental impact in wind turbine demolition is critical. This includes managing emissions, especially for large components such as blades and towers. Collaboration with environmental organizations to undertake habitat conservation and restoration can help balance wind turbine demolition’s environmental effects.

Identifying Additional Considerations

Beyond recycling and mitigating impact, there are other important environmental considerations. For instance, site restoration helps minimize disruption to local ecosystems and communities following wind turbine demolition. Specifically, site restoration involves the replanting of native vegetation and the cleanup of debris to ensure the area is returned to its natural or intended state.

The Future of Wind Turbine Demolition

With the evolving renewable energy sector, particularly wind energy, practices for wind turbine demolition will also change. The future will likely see advancements in technology, such as the potential use of robotics and advanced cutting techniques, leading to safer and more cost-effective demolition methods.

The challenge of increasing wind turbine size and power is also present. As turbines become larger and more powerful, the demolition process will become more complex.

Innovations in Turbine Manufacturer Variables

Innovations in wind turbine design could significantly impact the future of turbine demolition. For example, modern wind turbines are equipped with special blade coatings and heating components as part of cold-weather packages to reduce ice accumulation, which is crucial in maintaining optimal wind speed for energy production.

The potential development of self-disassembling turbines by manufacturers could drastically reduce the need for extensive manual labor and heavy machinery during demolition.

Small Wind Turbines and Urban Settings

The advent of small wind turbines in urban areas will necessitate adjustments in safety requirements. These turbines must be certified for safety, performance, and durability by reputable organizations, such as the Small Wind Certification Council and UL.

Scaling Up Safety Measures

The growing size of wind turbines will require a corresponding scale-up in safety measures. This might include:

- Increased use of advanced technology, such as drones for site assessment and inspection

- Real-time monitoring systems for structural integrity

- Virtual reality training for workers

Existing regulations will also need to be reviewed and updated to ensure they match the current scale and technological complexity of wind turbine demolition.

Summary

Wind turbine demolition is a complex operation that involves careful planning, rigorous safety measures, and a keen awareness of environmental impact. From the scale of modern wind farms and the high-stakes heights involved to the intricacies of construction and heavy demolition operations, each phase presents unique challenges that require innovative solutions. As we look to the future, advancements in technology, changes in turbine designs, and a focus on scalable safety measures can contribute to safer, more efficient, and more environmentally friendly demolition practices. The wind energy sector is a rapidly evolving industry, and as we continue to harness the power of the wind, we must also rise to the challenges of responsibly managing the lifecycle of these colossal structures.

Frequently Asked Questions

What are the main challenges in wind turbine demolition?

The main challenges in wind turbine demolition include the large scale of modern wind farms, the heights involved, and the complexity of the construction and demolition operations. These factors make the process intricate and demanding.

What safety measures are implemented in wind turbine demolition?

In wind turbine demolition, safety measures such as hazard evaluation, site-specific planning, fall protection measures, and emergency response capabilities are implemented to ensure a safe process for workers and the surrounding environment.

How are environmental considerations addressed in wind turbine demolition?

Environmental considerations in wind turbine demolition are addressed through recycling and reusing materials, mitigating environmental impact, and restoring the site post-demolition. This helps minimize the ecological impact of the demolition process.

What future considerations exist in wind turbine demolition?

In the future, wind turbine demolition will likely involve innovations in turbine design, safety requirements for small wind turbines in urban areas, and scaling up of safety measures. These factors will be important to consider for the future of wind energy.

How are innovations in technology influencing wind turbine demolition?

Innovations in technology such as robotics, advanced cutting techniques, real-time monitoring systems, and virtual reality training are enhancing safety and efficiency in wind turbine demolition. These advancements have the potential to revolutionize the demolition process.